Press conference on the new process of "Light Wave Killing" and the commissioning of the f

April 13-14, Hubei Hanjia Liu's tea industry held a "light wave killing" new technology and fully automated production line put into production press conference. Participating in the meeting were our chairman Ji Tianren, marketing general manager Diao Yu, Hanjia Liu's chairman Liu Jianguo, deputy director of the Provincial Department of Agriculture Ma Liangping, the provincial agricultural industrialisation office in charge of Hu Xiaoti, the Provincial Academy of Agricultural Sciences, executive vice president Xiong Jianping, the province's tea science and technology system of the chief expert Gong Ziming, the city's deputy director of the Office of the Deputy Director of the City Agricultural Office Lei Yunjiang, the city's science and technology bureau chief Qiao Hailin, Hubei Daily, Hubei Television, Xiangyang Daily News, Xiangyang Evening News, Xiangyang TV, Gucheng TV and other unit leaders, experts, journalists more than 60 people. Participants visited the Han family Liu's light wave killing process and fully automated production line of famous tea.

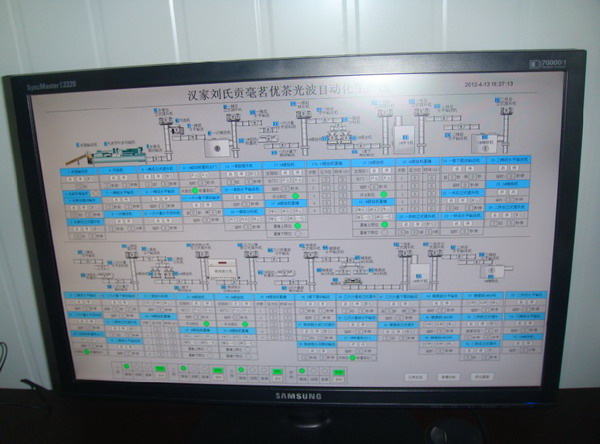

This has the international advanced level of production line, is my company for the main force and Hubei Hanjia Liu's tea company, Hubei Provincial Academy of Agricultural Sciences, Xiangyang Academy of Agricultural Sciences, Gucheng County Agricultural Bureau of the Tea Office joint research and development, with independent intellectual property rights of the domestic ** full-automatic, continuous, clean, modernised, light wave tea industry professional production line. Its characteristics are very obvious: at present, the domestic famous green tea is taken to heat transfer method of killing process, colour and fragrance can not be both. The production line is the first in China to use light wave killing, coupled with the use of automatic aroma machine, not only does not damage the green colour of green hair, but also to maintain the aroma of fresh and long-lasting, sweet taste, so as to develop a new variety of light wave tea.

Professor Ji Tianren, the 70-year-old chairman of our company, was the director and professor of the laboratory of the Institute of High Energy of the University of Electronic Science and Technology for a long time, and he was determined to transfer aerospace science and technology to civilian use. After years of efforts, invested a lot of human, material and financial resources, and finally developed the "light wave greening" process and fully automated production line production, light wave greening is the great innovation after the traditional famous green tea greening process, set microwave, infrared, hot air as a whole, the theory of tea production and expert experience in close conjunction with the technology, to achieve the second leap forward in the green tea greening process in China. The production line equipment is researched and developed according to the requirements of the production process and combining various disciplines (material, thermal engineering, machining, automation control, etc.), the process is scientifically designed, environmentally friendly and energy-saving, and the quality of the products is stable and the aroma is unique.

Hanjia Liu's chairman Liu Jianguo said, Hanjia Liu's use and Rui microwave company to develop the main force of this "light wave killing" new technology and automated production, production costs have been greatly reduced. The use of traditional processing technology, a kilogram of dry tea consumed 4 yuan of coal and electricity, 4-6 yuan of labour, the use of the new process, the cost fell to 3 yuan, 2-3 yuan, respectively, to save energy, labour 25%, 50%. Moreover, the traditional process by human influence factors are too large, the product quality is not stable, the use of new technology, ** degree to reduce the impact of human factors.

Hubei Provincial Academy of Agricultural Sciences, director of the fruit and tea, the chief expert Gong Ziming personally tasted "light wave tea", said the international tea processing and production areas for the first time the systematic use of "light wave killing" technology, is China's current advanced tea production line, leading the tea processing in China! The future direction of China's tea processing, has a milestone significance. By choosing the same material and the traditional process of comparison, with the roller killing and "light wave killing" way of comparison and sensory evaluation, the results show that: with four kinds of tea samples for comparison, namely: traditional one, traditional two, light wave one, light wave two, comparison results show that the light wave tea than the traditional tea in the characteristics of: the appearance of the colour and luster is more green, oily, more fine and beautiful stripes. Oily, more fine vertical straight hair, soup colour is more green and bright, the aroma of chestnut is more persistent, the taste is more fresh and mellow, the bottom of the leaf is more tender and green and bright. Provincial and municipal Academy of Agricultural Sciences, City and County Science and Technology Bureau leaders on the success of this technology fully affirmed. Experts Xiong Jianping, Gong Ziming, Yu Huaqiang, Zhang Yaohua, Jiang Shaobo, etc. have participated in the development of the process for many times, and are very satisfied with the current "light wave killing" new technology and fully automated production line, which is considered to be a great contribution to China's tea industry, and said to further participate in the development of technology and fully automated equipment development, in order to achieve the best.

中央控制室

鲜叶

光波杀青叶

- > As it turns out, a CVD di··· 2023-07-21

- > Henan Becomes World's Lar··· 2021-11-10

- > New product release - Our··· 2016-03-16

- > Press conference on the n··· 2012-04-20

Recommended Products